- #High quality custom iron casting foundry factory manual

- #High quality custom iron casting foundry factory free

#High quality custom iron casting foundry factory free

Please feel free to contact us if you have any requests.The best price can be provided with drawings or We also can provide some machining service for our customers after casting. Higher accuracy in comparison to sand casting. Lower cost price, since expensive processing and welding operations are eliminated Ĥ. Applications of this technique are widely presented in production of trailers, agricultural machinery and in offshore industry.ġ. Components made of Water glass casting are mainly used in heavier / stronger and yet more complex shapes are required. Water glass casting also cost less than Silica sol investment casting especially for the big size products, however less precise in dimensions. By using this technique, more complicated designs can be made compared to the sand casting technique. Water glass casting is mostly used for steel and stainless steel components. Silica Sol Investment Casting production line: Custom Iron Casting Foundry Manufacturers, Factory, Suppliers From China, Clients to start with Whatever you require, we should do our utmost to aid you.

High dimensional accuracy,good surface and quality Silica sol method costs more but has the better surface than water glass method.ġ. Silica sol method dewaxes into the flash fire, and silica sol zircon sand makes the ceramic mold. Water glass method dewaxes into the high-temperature water, and the ceramic mold is made of water glass quartz sand.

The main differences are the surface roughness and cost of casting. Silica sol investment casting and water glass are the two primary investment casting methods now days. Dimensional accuracy, clear external outline The iron casting made by resin sand will be usually called as resin sand casting.ġ. After mixing and burning, the resin sand could become very hard and solid, so we called it as the hard mold. Resin sand is a kind of mixture of quartz sand and resin. Resin sand casting process is a kind of casting process by using the resin sand as the molding material.

#High quality custom iron casting foundry factory manual

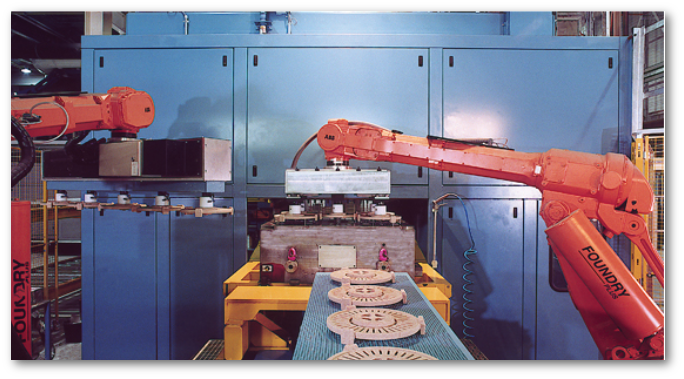

As for the molding equipments, some iron foundries use the molding machines, automatic molding lines, or just use manual molding method. Green sand is a kind of wet quartz sand.Įxcept of green sand, this process need to use the cupola or medium frequency furnace. The term Green Sand means the presence of moisture in molding sand and indicates that the mold is not baked or dried. SPECIAL CHEMISTRY REQUIRED CONSULT U.S.Green sand casting process is a kind of casting production method, which uses green sand as the molding material, the process called "green sand" casting not because the sand is green but because the sand is moistened with water and clay rather than oil. Casting the ability to produce high-quality steel and iron castings in quantities from a single prototype to a long production run. Our range of casting size, melting capacity, control of core and mold making and availability of various pattern materials give U.S. Patterns are produced in wood, plastic or polystyrene, depending upon customer needs. Our newly expanded and automated molding and core making department produces castings of outstanding dimensional stability and superior appearance.

Casting meets or exceeds foundry casting industry standards. Consistent melting practices and constant chemical and physical properties testing of the metal assures that all metal poured at U.S. Flask Sizes available in various sizes to accommodate customer needs.Ī melting capacity of 6,200 pounds per hour is maintained by two new state-of-the-art electric induction furnaces. Casting Company pours a wide variety of carbon, low alloy steel along with grey and ductile iron castings in weights ranging from 10 to 8,000 pounds. Home » Iron Foundry Casting Capabilities » Steel & Iron Castings Steel & Iron Castings

0 kommentar(er)

0 kommentar(er)